New Zealand company Trudesign manufacture a complete range of composite marine fittings and valves. Unlike many companies Trudesign keep everything in house, design, tooling, and manufacture. Like us, Trudesign produce a quality product which we whole heartly support and endorse. All products are made of the latest high impact resistant composite plastic materials designed to meet the demands of the modern boating industry and the ISO Marine Standards.

Trudesign Marine Fittings

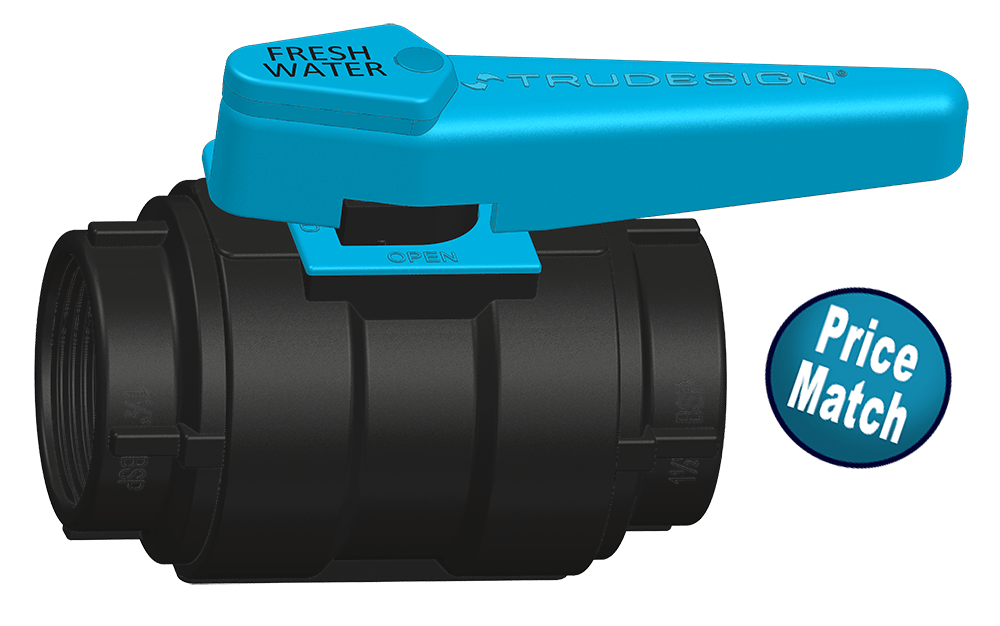

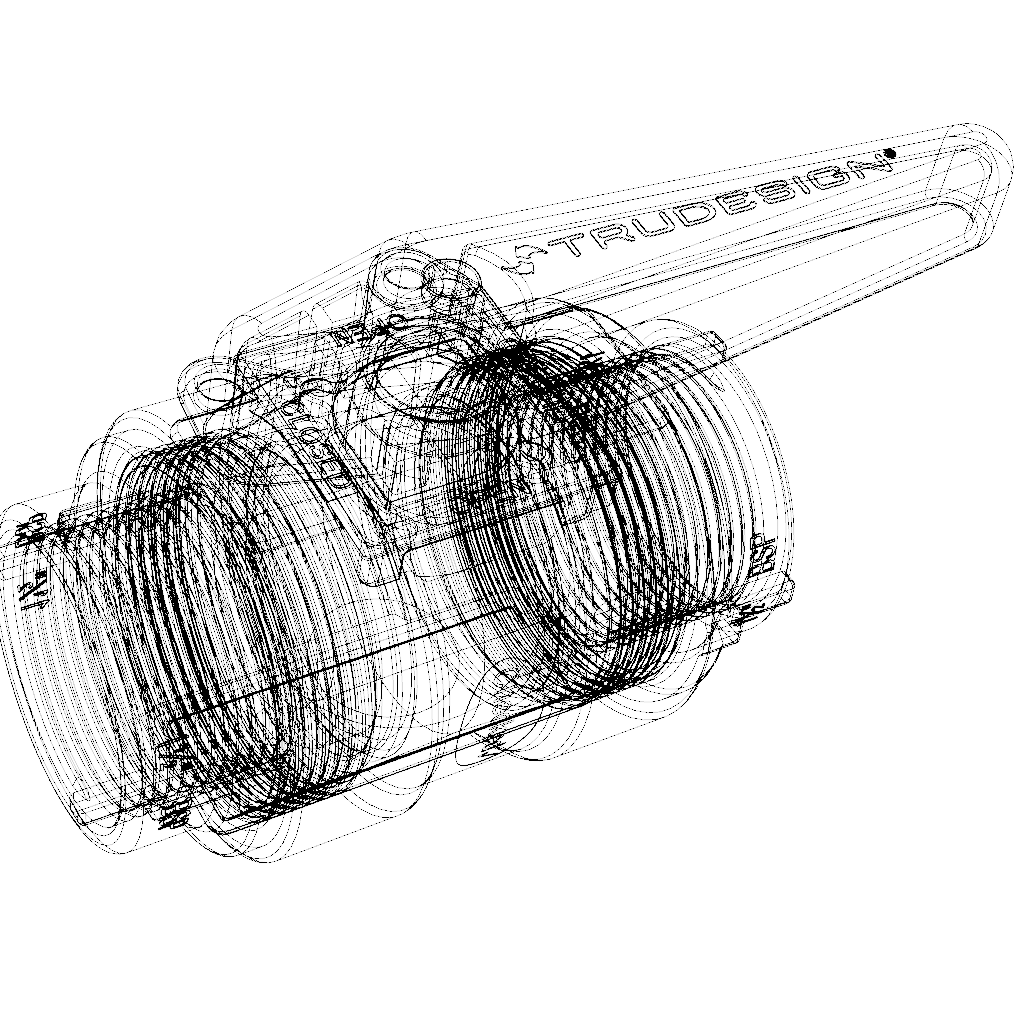

Trudesign Ball Valves

TruDesign’s fully approved ball valves are designed for use in marine applications above and below the water line. Manufactured in glass-reinforced nylon composite, they are strong, impact resistant and light in weight.

The valves are corrosion free and do not suffer from electrolysis. The ball and sealing rings utilize a PTFE polymer to ensure a smooth action which will last for many years.

Trudesign ball valves require little or no maintenance. No oil or grease is required just simply turn the handle a couple of times a year and you’re done.

Full Bore

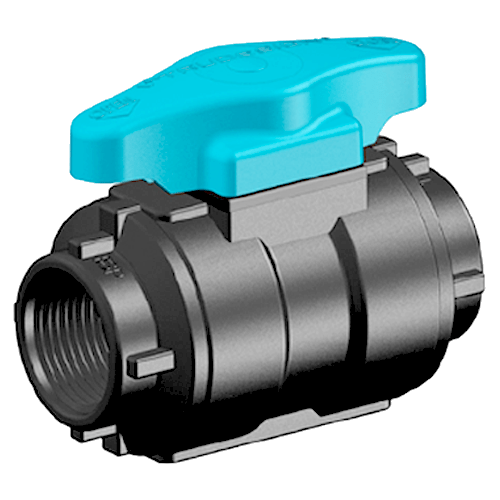

Tee Handle Option

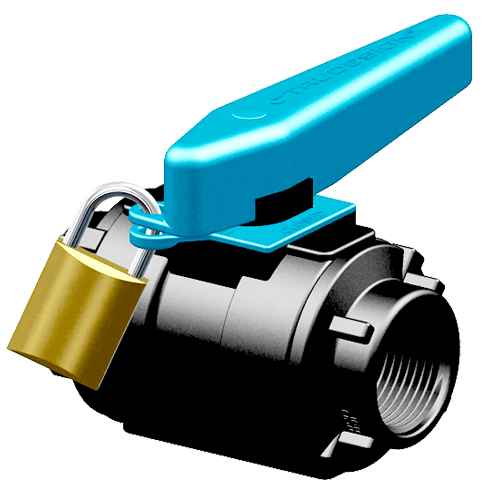

Locking Ball Valve

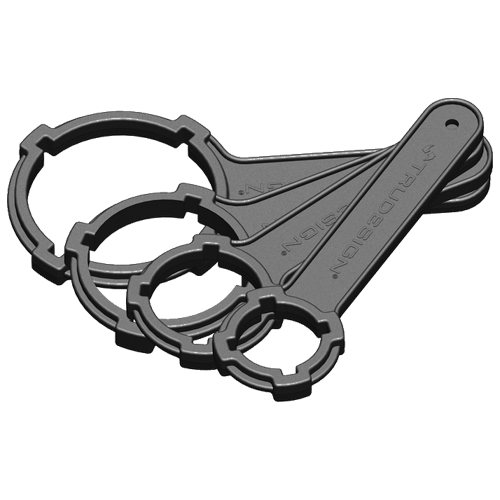

Ball Valve Spanners

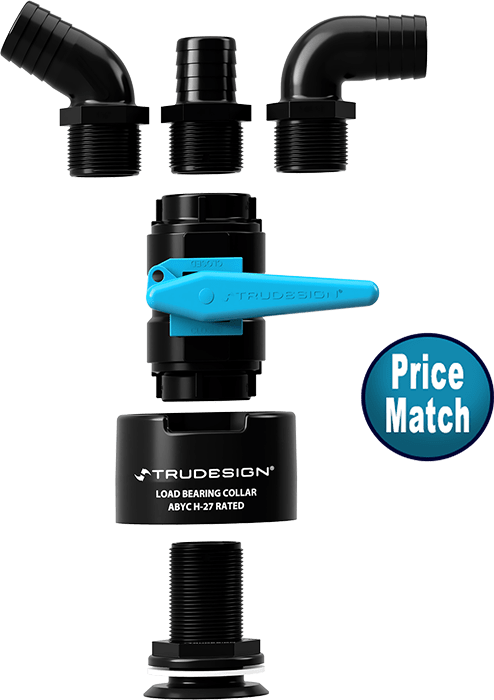

Seacock Kits

Choose the kit size and hose tail that you want. We pack our seacock kits complete with the load bearing collar for a few extra pounds it just makes sense to do so.

The load bearing collar increases the static load to 500Ib (227 kg).

Seacock kits are available from ¾ – 3” choose a straight, 90° or 120° hose tail. An optional Tee handle can be used in tight spaces.

Ball valve and skin fitting installation tools are available.

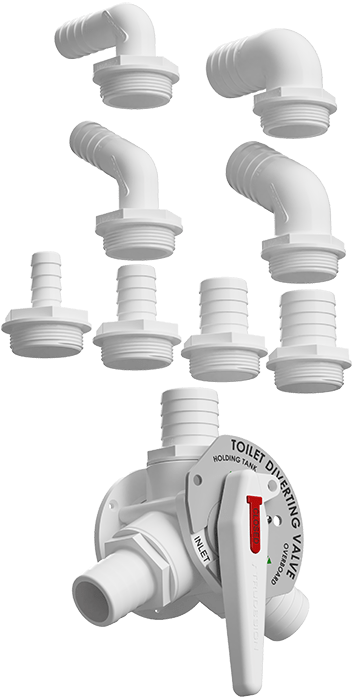

Trudesign Aquavalve

Manufactured from a glass reinforced nylon composite the Trudesign Aquavalve combines high strength and minimal weight. 360 hose tail combinations make this unit truly flexible.

- Stainless Steel Fasteners

- Easy installation

- Elbow or straight hose tails

- Lockable

- Behind bulkhead option

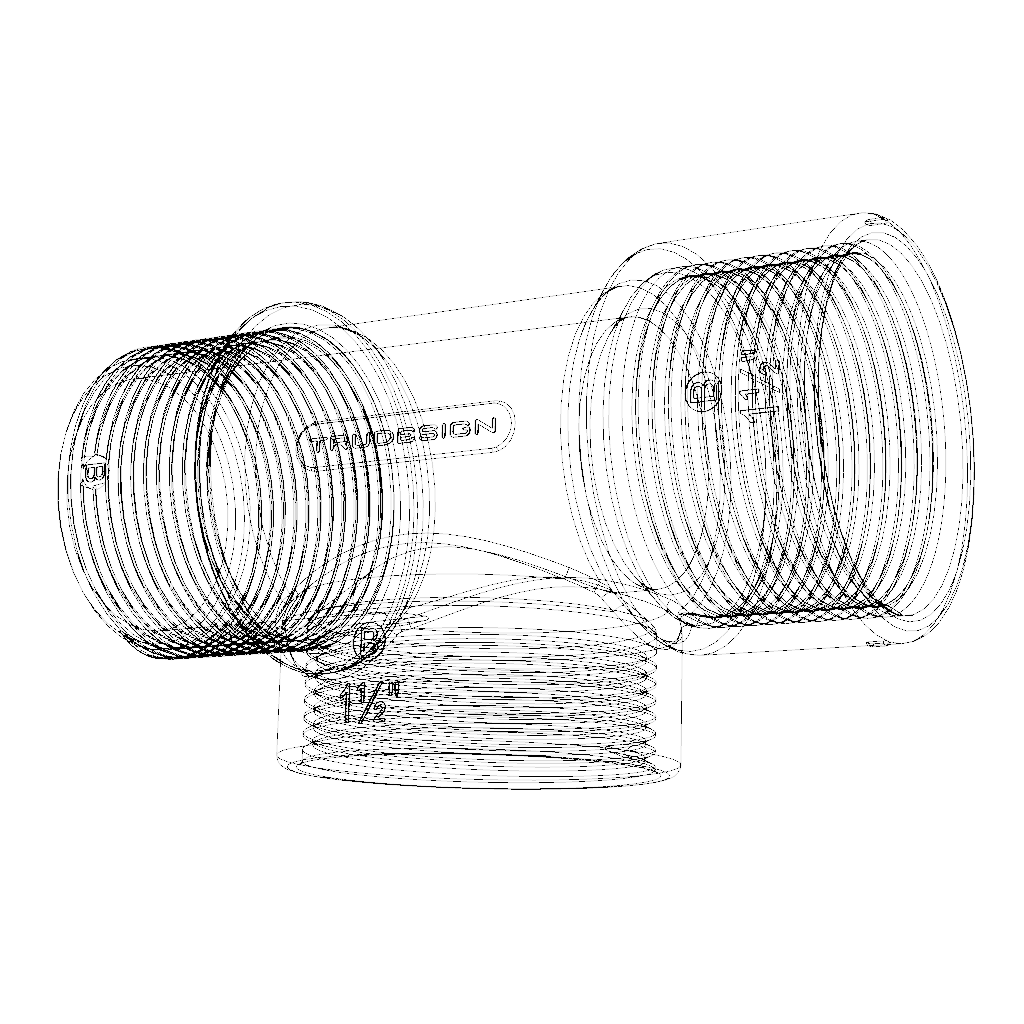

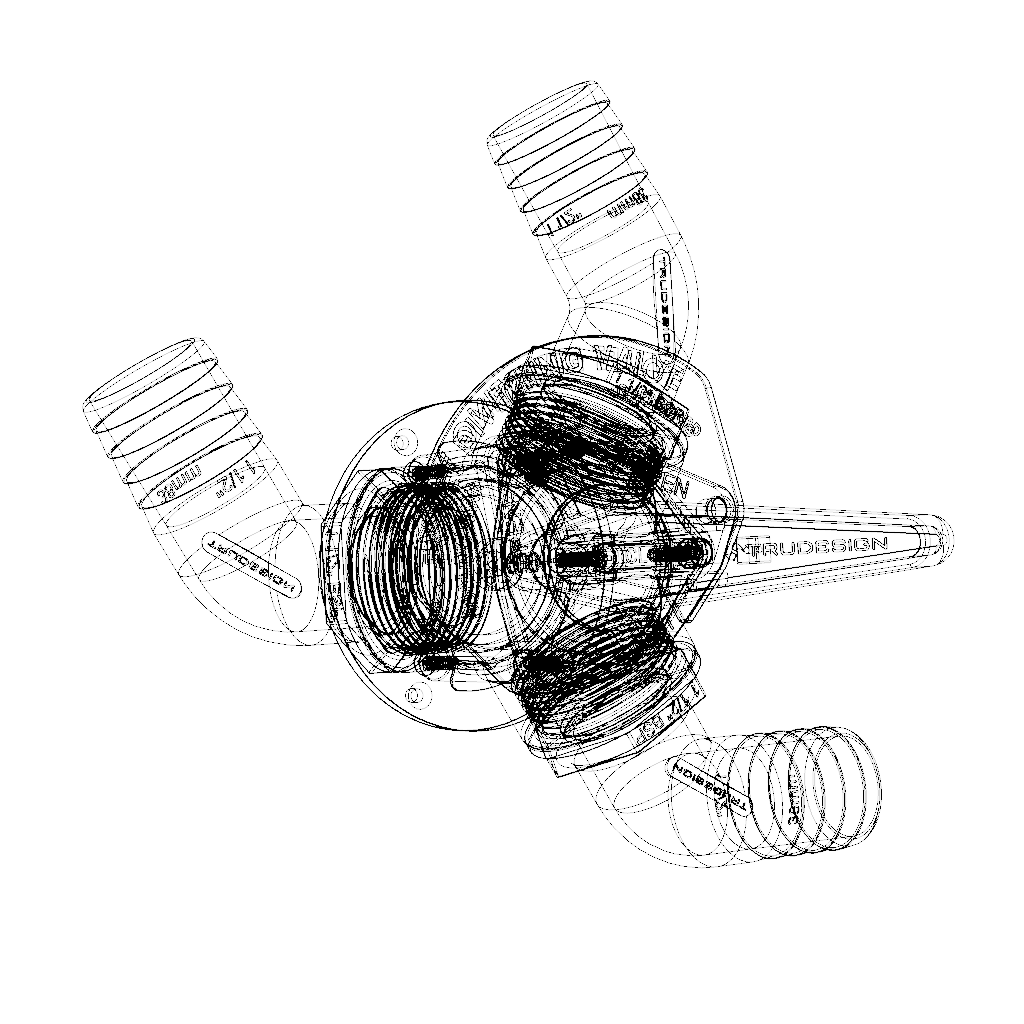

Attention CAD Designers

DROP TRUDESIGN

INTO YOUR 3D

MODELS.

STEP FILES

AVAILABLE

Trudesign Manifold

We are fitting more and more kit in our on boats these days, such as water makers, gen sets, air conditioning etc. The engine, the galley sink and toilets all call for seawater. A single Trudesign seacock and saltwater manifold could deliver seawater to each unit meeting demand. There are advantages but there are disadvantages of installing a manifold (Sea chest) too.

To find out more contact the sales team today. Tel: 01320 520830

Saddle Clips and Bases

These are great!

Screw or epoxy the saddle base in position. Clip on the hose grips. When you push your hose in place the grips are forced to bite down even tighter on the base.

A great design!

These can be use with cable ties adding additional security and could keep your cable runs secure and tidy

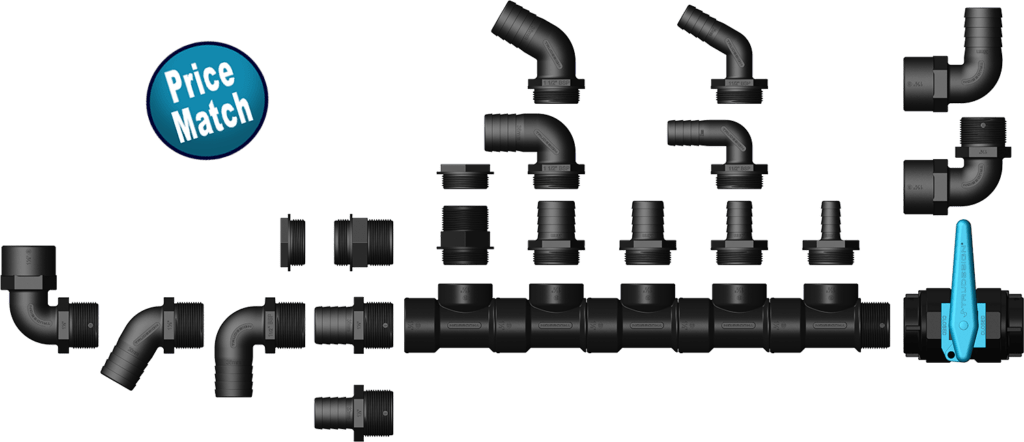

Hose tails, reducers, straight connectors, Y pieces and more…

We carry a full range of Trudesign fittings at competitive prices. Click on the link and look through the pages of fittings available. If you have any questions, contact the Sales Team on Tel 01420520830 we will be more than happy to answer your questions.

Address

Tek Tanks Ltd

The Old Stables, West End Farm,

Upper Froyle, Alton, Hampshire,

GU34 4JR England

Tel: +44 (0)1420 520830

Email: sales@tek-tanks.com

Visits: By Appointment Only

Copyright 2023 Tek tanks Limited all rights Reserved | Company Registration No: 3857992 | Vat Registration No: 744959483

Privacy Policy Link | Terms & Conditions Link | Design by Technocrackers.